- Call : 0356253183

- Email : admin.assistant@dmmeng.com.au

Customer Challenge:

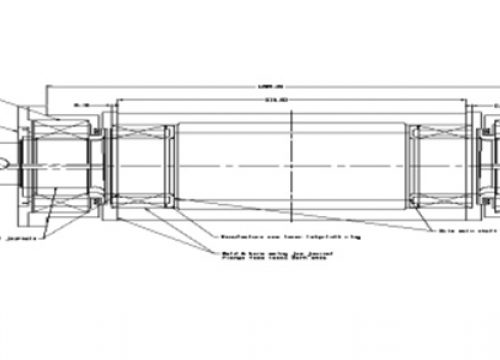

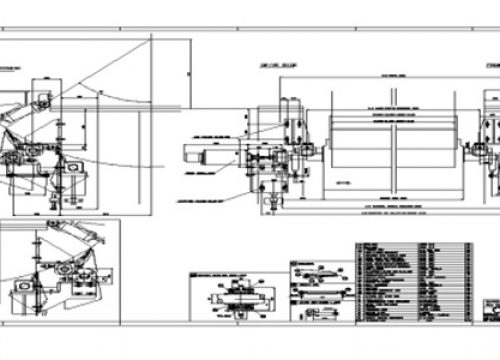

To safely and cost effectively repair the pin holes that retain the cutter and pre cutter dredge buckets, back to OEM specifications on both the radial and cord dimensions, while the dredge is still in the working pit area, to reduce dredge downtime.

DMM eng Innovative Solution:

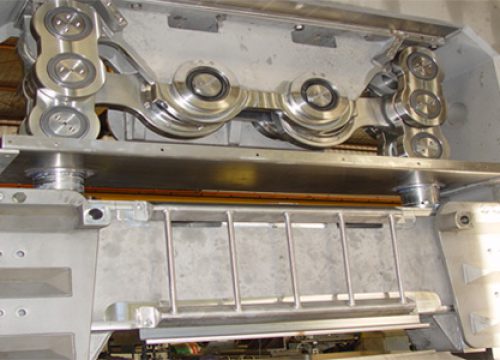

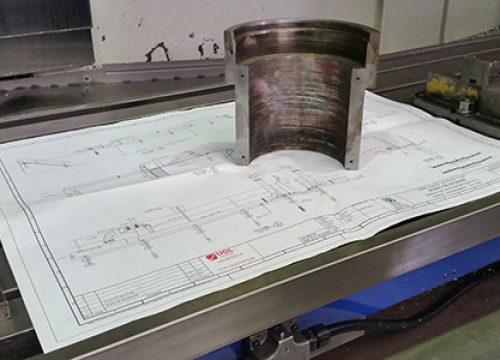

DMM eng developed an in-situ refurbishment process, utilizing a custom engineered jig that enabled the bearing housings to be preset so when the line boring bars are assemble for boring the OEM specification are

accurately achieved.

Service Delivered :

The DMM eng team of six staff, working two ten hour shifts over six days and nights, using two Line Boring units in parallel, enabled the task to be completed in a fraction of the time taken in previous attempts, allowing the dredge to resume full production as scheduled.

Customer Benefit:

Huge time saving compared to previous methods and with greater final accuracy, which prolongs cutter and pre cutter wear and enables high production rates for longer.

Download PDF