- Call : 0356253183

- Email : admin.assistant@dmmeng.com.au

Customer Challenge:

A critical high pressure steam control valve failed on the eve of the Anzac Day holiday weekend. The valve had to be repaired promptly to enable the plant to restore full power generation output by the following Monday. Delayed repair would result in substantial downtime and lost revenue for major power industry customer.

DMM eng – Innovative Solution:

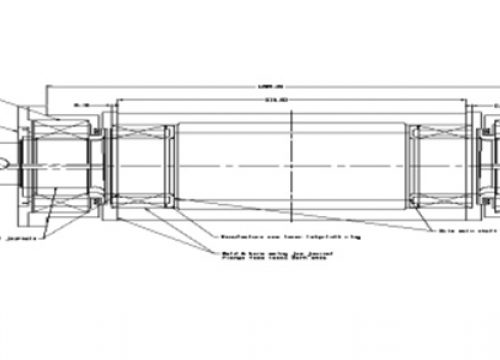

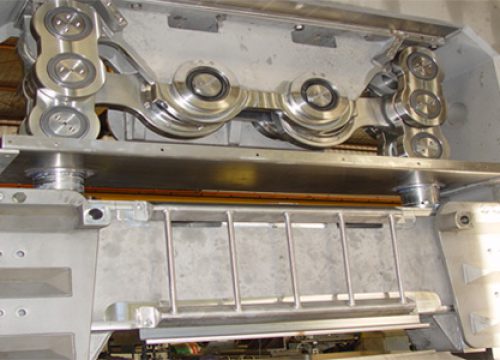

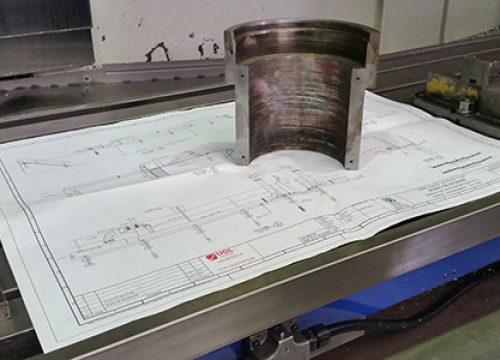

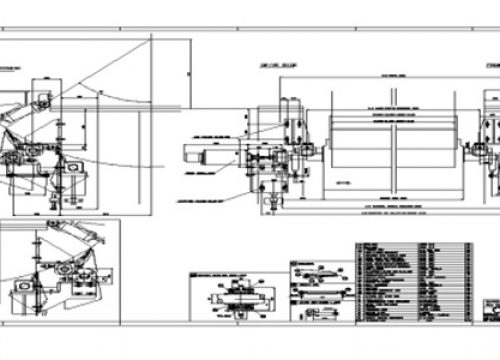

Repairing the valve body in-situ was evaluated as the fastest and safest method, however this required a team of three specialists with line boring

expertise and equipment. The team was identified and mobilized by early morning Anzac Day and the valve body seat was repaired, pressure tested and returned to service within 3 days and in readiness to meet peak power demand on the Monday morning.

Service Delivered :

Specialist team identified, equipment modified, tested and deployed within 12 hours to enable the repair to be completed safely and on time over the Anzac Day long weekend holiday period.

Customer Benefit:

Power generation returned to 100% of capacity within the planned time frame, delivering revenue and at a substantially reduced time and cost compared to conventional valve removal and repair.

Download PDF