- Call : 0356253183

- Email : admin.assistant@dmmeng.com.au

Customer Challenge:

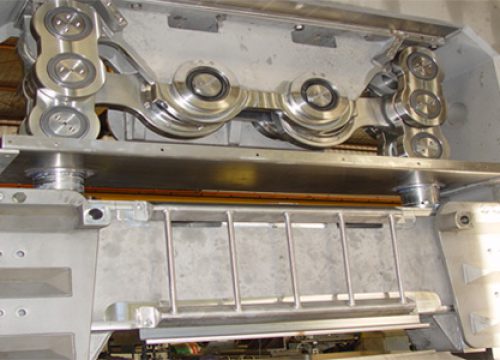

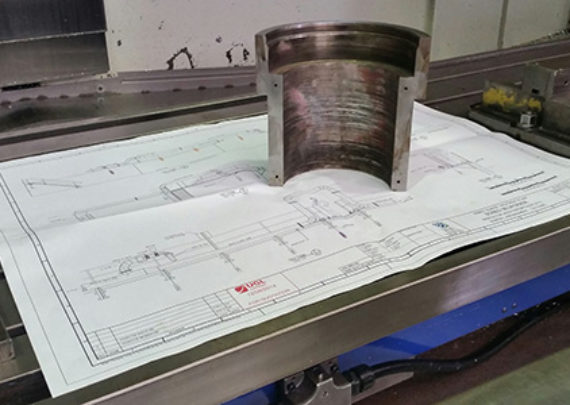

A critical safety system coupling failed in service, all spares were exhausted and a replacement unit would have previously been OEM sourced from Germany, with an approximate lead time of 3 months and at a cost of $30k per coupling. The coupling failure reduced the coal handling feed rate to the power station by 50% , with a substantial downtime cost.

DMM eng Innovative Solution:

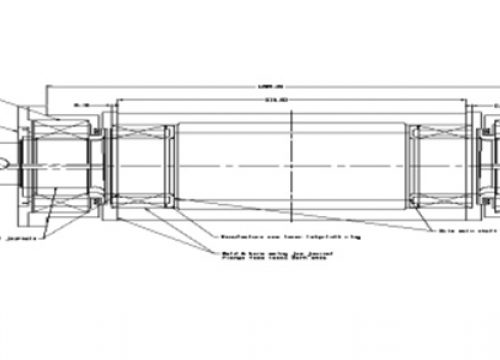

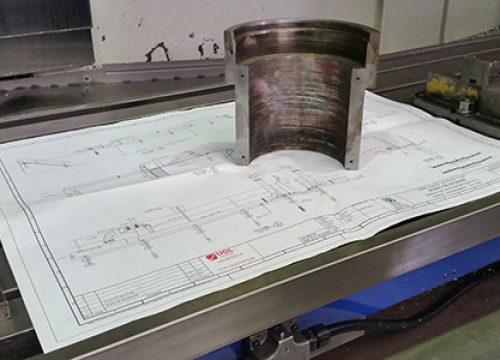

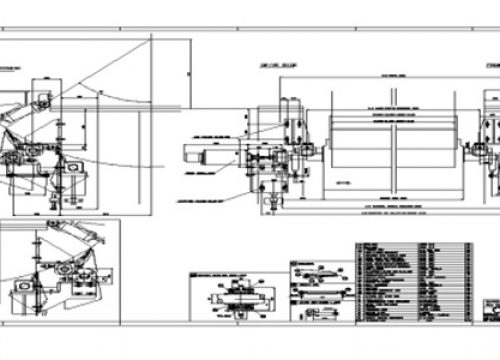

A detailed drawing was drafted for future reference, the workshop repair solution included TIG welding, metal spraying and complete pressure testing and verification to the OEM specification.

Service Delivered :

DMM eng arranged urgent pick up of the damaged coupling, scoped the task, repaired it to OEM specifications and enabled it to be returned to service within a 7 day turnaround time.

Customer Benefit:

Installation of the refurbished coupling enabled coal handling through put to be returned to 100% of capacity within a fraction of the time compared to waiting for a replacement coupling to be manufactured and shipped from Germany. This restored full operating revenue and at a substantially reduced cost versus a replacement unit. Local capability has been developed to enable additional units to be manufactured and stored.

Download PDF