- Call : 0356253183

- Email : admin.assistant@dmmeng.com.au

Customer Challenge:

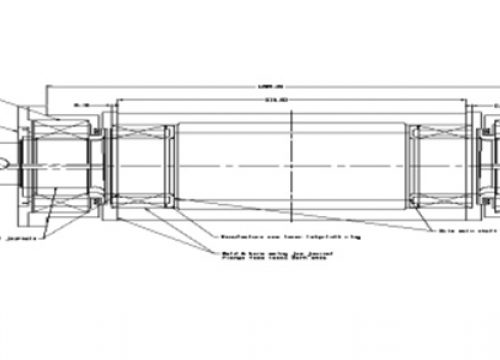

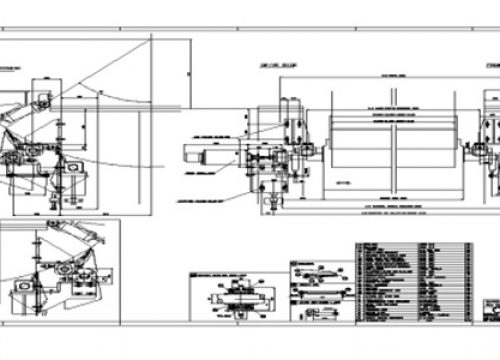

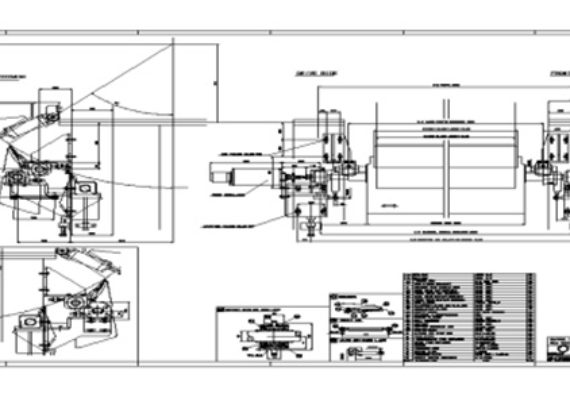

The Yankee dryer creping doctor blade assembly on the tissue machine was scheduled to be replaced during a limited duration production shut down. The tasks were on the critical path for the scheduled shutdown, which put added pressure on the planning and execution of the tasks. The complexity of the tasks required superior engineering expertise to ensure a complete and on-specification installation.

DMM eng Innovative Solution:

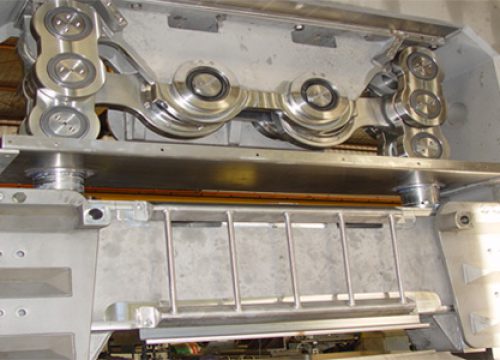

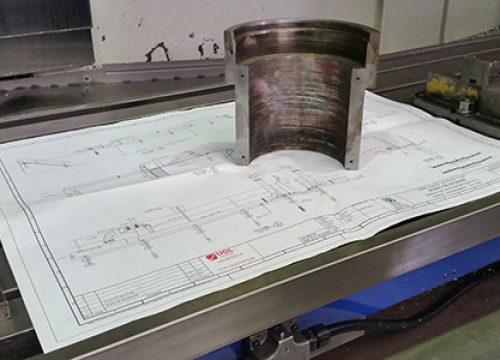

Recognising the time and criticality of the tasks, DMM eng designed, fabricated and pre-tested a specialised jig to enable the exact alignment and engineered solution to be completed within the downtime schedule.

Service Delivered :

The DMM eng team of 3 staff per shift, worked across 2 shift cycles to complete the work plan, which was inspected and verified correct by an expert flown in from Italy to supervise the quality of the upgrade.

Customer Benefit:

The Yankee rebuild and upgrade was completed faster than scheduled, with precise and exact alignment achieved, which enabled the tissue machine to return to full production earlier than planned.

Download PDF